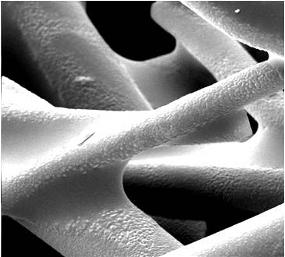

Cross-Linked Microstructure(CLMTM) Technology

Fiber-based CLM™ structures have high porosity and strength, customized pore morphology, and controlled bulk mechanical properties as compared to traditional products. Core physical and processing elements of CLM™ include:

|  |

CLM™ was developed and commercialized during a five year period and refined through more than 1600 experiments resulting in an intellectual property portfolio of 16 issued US patents and more than 30 additional applications.

Bio2’s material scientists have created a master curve for CLM™ that allows for the control of several characteristics important in the orthopedic industry including:

Bio2’s material scientists have created a master curve for CLM™ that allows for the control of several characteristics important in the orthopedic industry including:

- Pore size: from <10 microns to >200 microns

- Pore morphology: uni-modal, bi-modal, tri-modal

- Fiber diameter: from <5 micron diameter to >200 micron diameter

- Fiber materials: bio-active glass, titanium, tantalum, alumina, silicon nitrate, and others

- Bonding materials: glass, ceramic, metallic, polymer

- Compressive strength: from 5 MPa to more than 50 MPa